— Industry 4.0 “BIG DATA”

A MODERN INSTRUMENT TO THE NEW PAPER MILL MANAGEMENT

Production Reports, raw materials, bobbins, winder and sheeter production cycles, steam, energy, gas, and so many other crucial parameters … Most of the time, these important variables being collected for cost controlling and management reporting, are processed in a semi-automatic or in a manual way, or most frequently using different software and other tools. But how to avoid transcription errors, computing, as well as getting all the data faster, easier and in a smarter and reliable way from the local working stations? How to get back to the main software used?

The solution is REDI Scalink®

Several PLC and DCS of the plant are connected to the system through an operator friendly interface, allowing the paper mill to acquire all the data from different machines. The Scalink® SW architecture shows its potentials by fulfilling, and providing, all the information required to the ERP plant platform, stepping up the entire system, enabling all the analysis and calculations. Eventually the system supports different protocols used (owned-office PLC-DCS-HW).

Our Scalink® platform, made for paper mills’ systems networking, without specific I/Os. The best choice for the customer.

- Flexible and Eaisy to drive:

- Multilevel architecture – enabling the strictly interfaces use, only;

- Based on a SCADA philosophy,

- Scalink® can be totally integrated to the Windows system, exploiting all the potentials arising from communication among native office stations.

- Very flexible, can be used form a remote desk – with few signals – up to the main desk with hundreds of signals:

- All the Industrial protocols available:

- Data storage every second, at least;

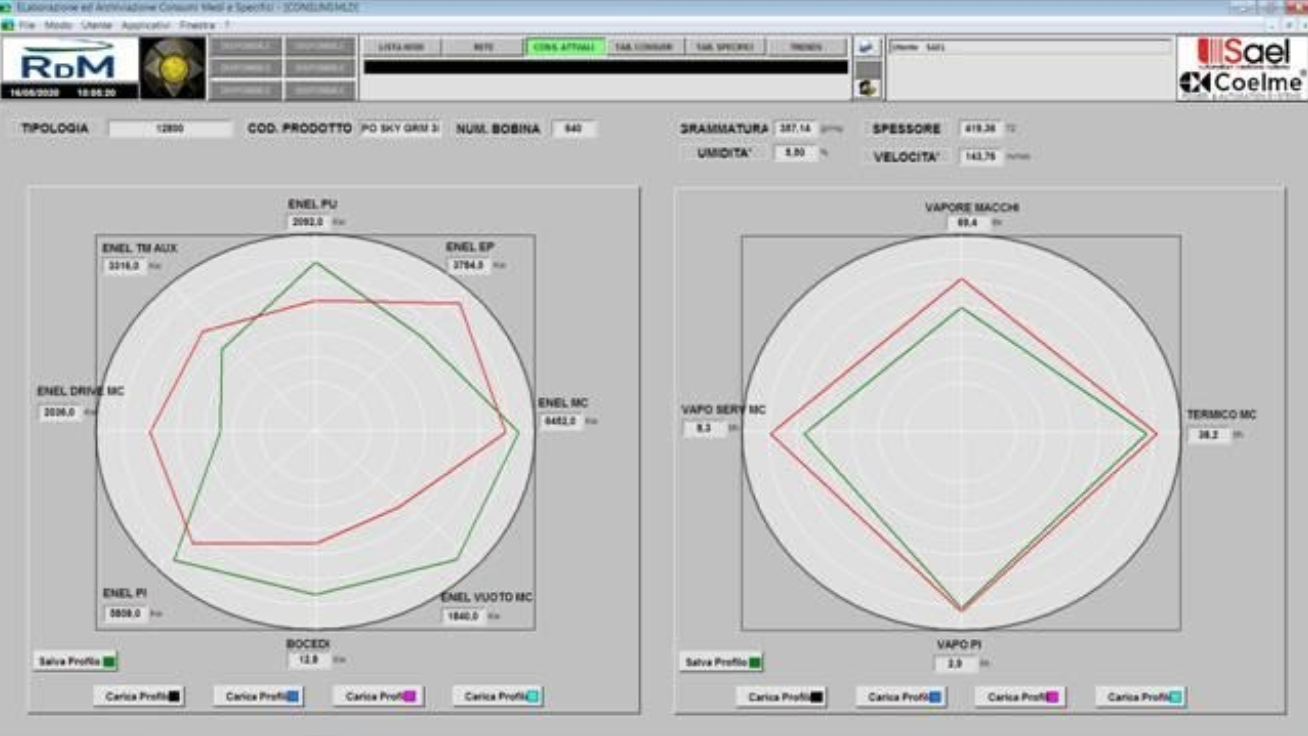

- Data showing on multiple version: graphics, text, tables, and so on;

— Function

Any single value even of a relatively larger scale size can be stored, historicized, and showed in a report way, independently to the original source – all related to the Hard Dick capability, of course -. Every variable can be treated by Excel or Access Windows programs, and resubmitted as a new variable after the calculation (production specific, energetics, etc.). This is why our Scalink® system has no barriers, computation wise.

— Which is the paper mill industry future?

There is no doubt that * data will play a strategic role in the modern industry, since they are becoming larger size & amount wise and of different characteristics, such as:

- Design data: data regarding designing machinery and products.

- Operation data: in relation with the equipment functionality and their components, as well.

- Efficiency of labor data.

- Costs data.

- Logistics data.

- Environmental and climatic conditions (internal/external temperature, humidity, noise) data.

- Fault and system health monitoring data.

- Quality product data (% of defective production).

- Product’s life cycle data (reparation, warehouse availability).

- Customers data (Market Targets, feedback from product usage, design suggestions).

— Industry 4.0 and DATA MINING

— Certification ISO 50001

— Big Data Analysis (costs and final balances)

— Data storage

- Bobbin code;

- Type of paper “Es: type 210 gr400”;

- Number of bobbin produced in monthly serie, grammature, meters produced, production start date, production end date, length, humidity, thickness, etc.

- and all the series of energy parameters “absolute” necessary for their production- from the steam to the electrical energy per area of the plant ( KW drive MC, KW free, KW purge. KW stock preparation, KW pulpers, KW head machine, KW auxiliary, steam stock preparation, steam MC, steam service…)

All these, supported from a rapid and simple search engine, permits to perform researches per product codes, per production periods or through customizable filters in order to always have in hand the trend of the final costs for the production of each roll.

Are you interested in learning more?

Contact us by filling out the form