— General overview

Over the years SAEL made a lot of those applications: from the overall application up to the single specific parts of the machine based on customer needs and investments.

The SAELs “Sectional Control” is the first automation & drive system without cascade MASTER CONTROL DRIVE, whose the intelligence is inside the AC or DC drive. This solution is awarded as the most complete system ever by a huge group of technicians and professionals. Actually it fulfils any modern paper mill need as much as winder or calander as well.

The reference control is managed by an AC or DC converter and supported by a 1 Mbit/sec CAN bus MULTI-MASTER network. This is miles away from the other systems based on PROFIBUS MASTER-SLAVE networks, allowing a faster data computing: 6 Mses for 60 AC or DC motors.

— Drives Sael

The main value selling features of our Drives as much as the main differences vs. competitors are:

– Reparability; Today the drive is assumed as a one shot component to be replaced in case of failure. Having a full reparable drive this is not the case of us, brining a concrete benefit to the users in term of cost effective and quick spare parts availability.

– Flexibility; Our drives are fully integrated with any existing equipment and fully compatible with the most common systems in market.

– Robustness; This is a must within the R&D concept. From the IGBT calculation up to the electronic board, the long life capacitors and the high speed calculation performance as well.

– Long Life; All the components used are based on that philosophy. The electronic regulation board is a typical long life device example. Thanks to the high performing main Microprocessor used the board can be upgraded on a firmware base at any giving time.

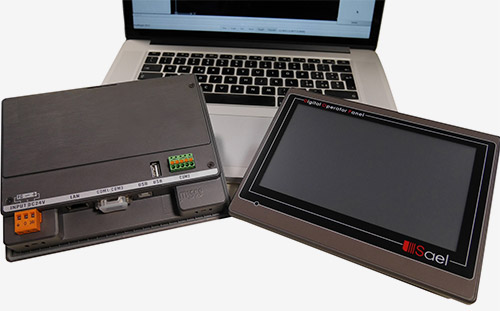

— Sectional controls DOP Touch

Having a Serial Port direct connection to the Drive, most of the time those devices are used to display speed or currents or alarms.

As mentioned above the DOP 2001 can manage the Drive internal variables – PID controls, Load cells, Electric shafts, Positioning; etc.; -. Moreover it manages a bunch of parameters formerly controlled by the PLC. Within the standard process DOP controls the following parameters:

- Cascade Speed Increase / Decrease value

- Single motor speed Increase / Decrease value

- Loop Recovery

- Real / Set Point Speed

- Sweep Display

- Drive and Motor ISO1 Alarm display

Are you interested in learning more?

Contact us by filling out the form