— General overview

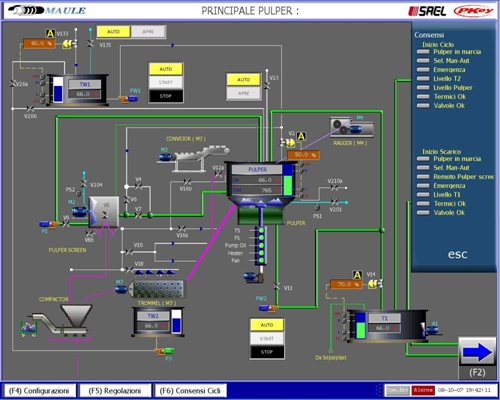

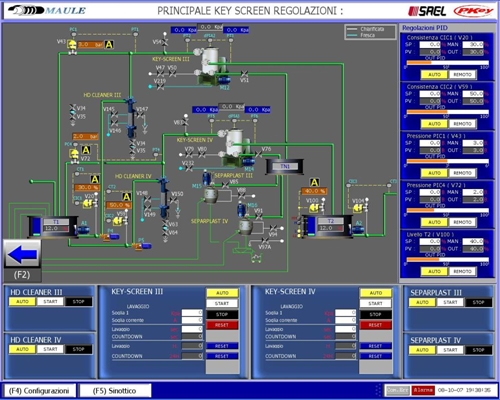

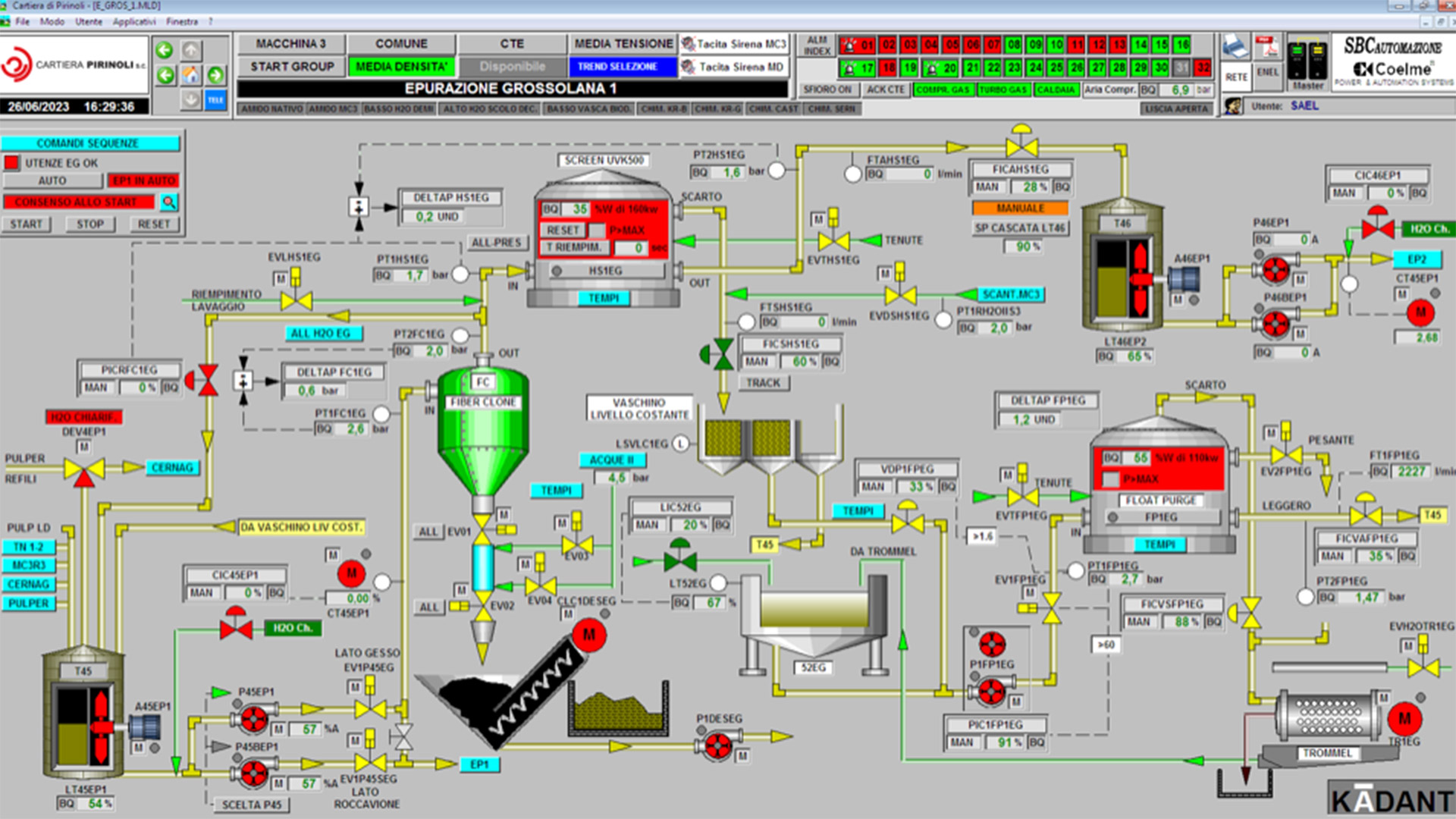

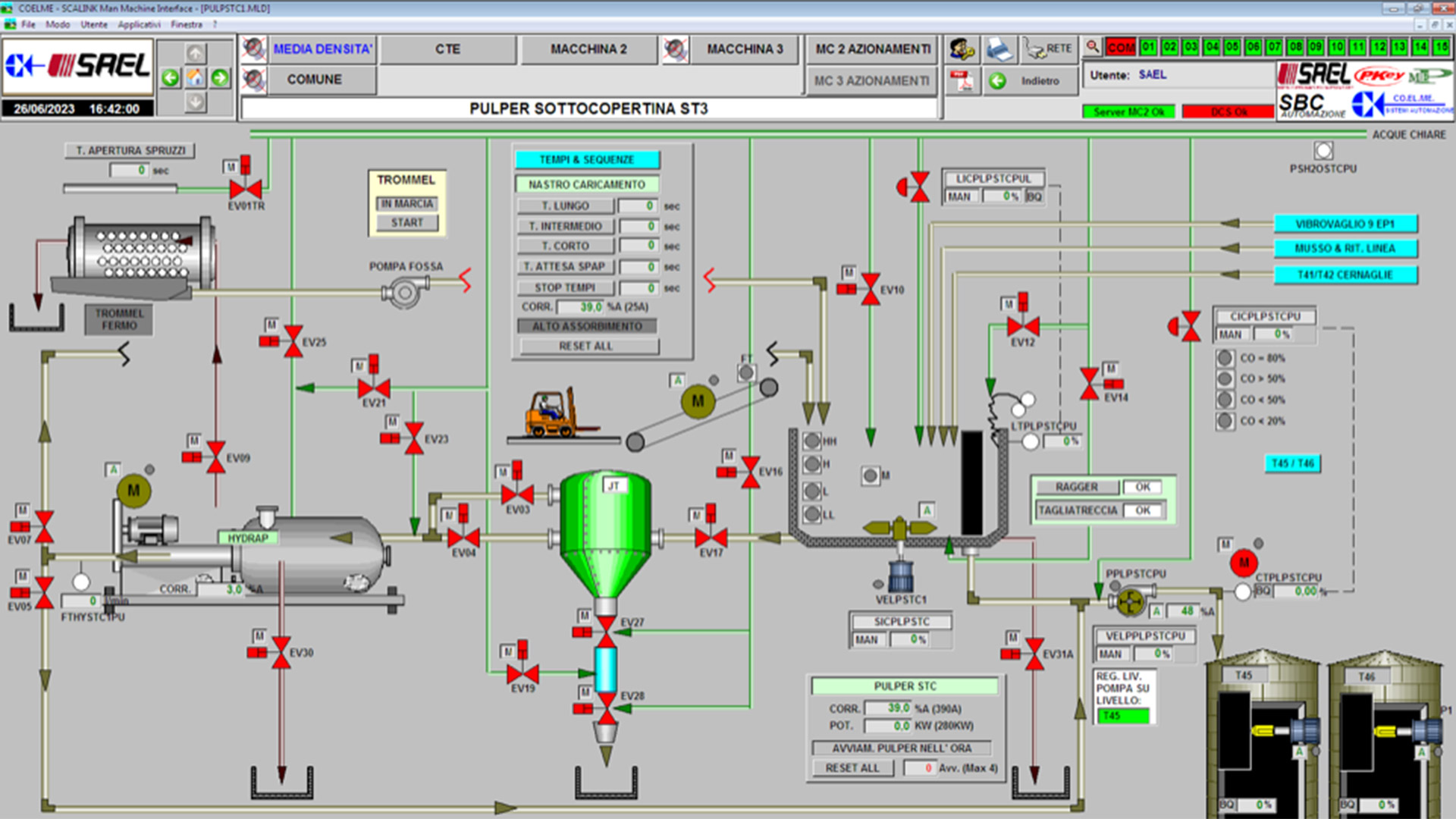

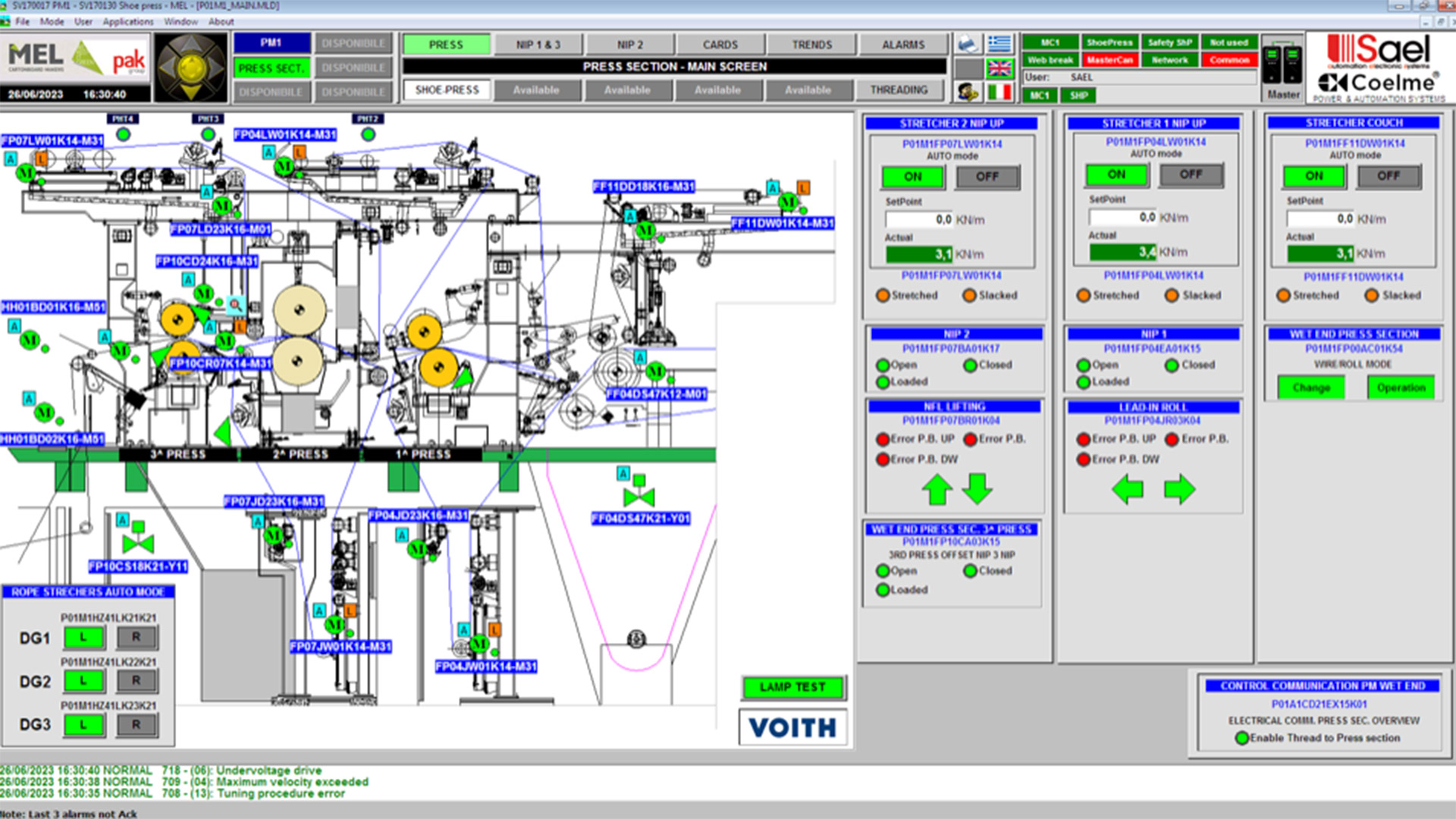

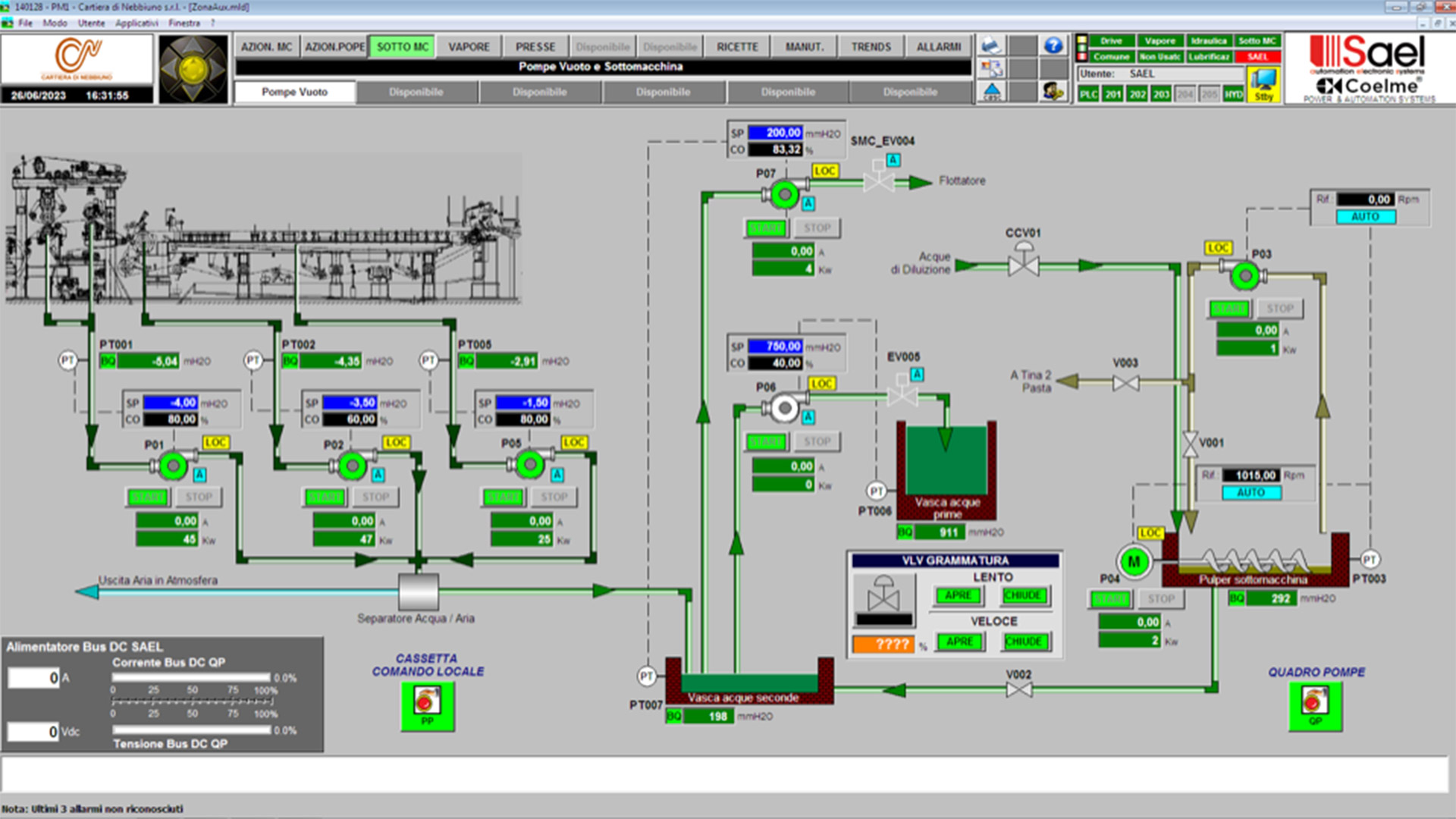

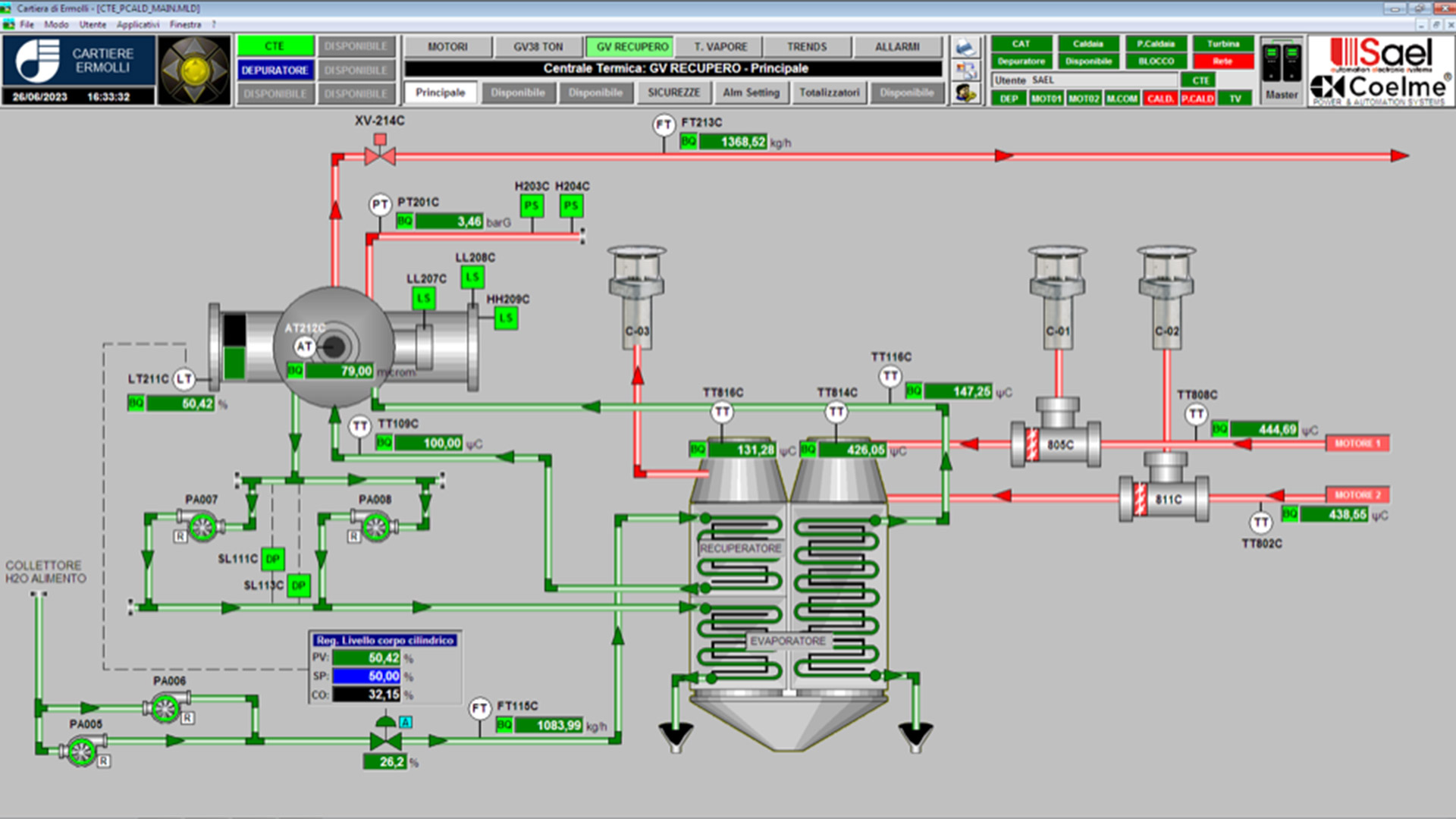

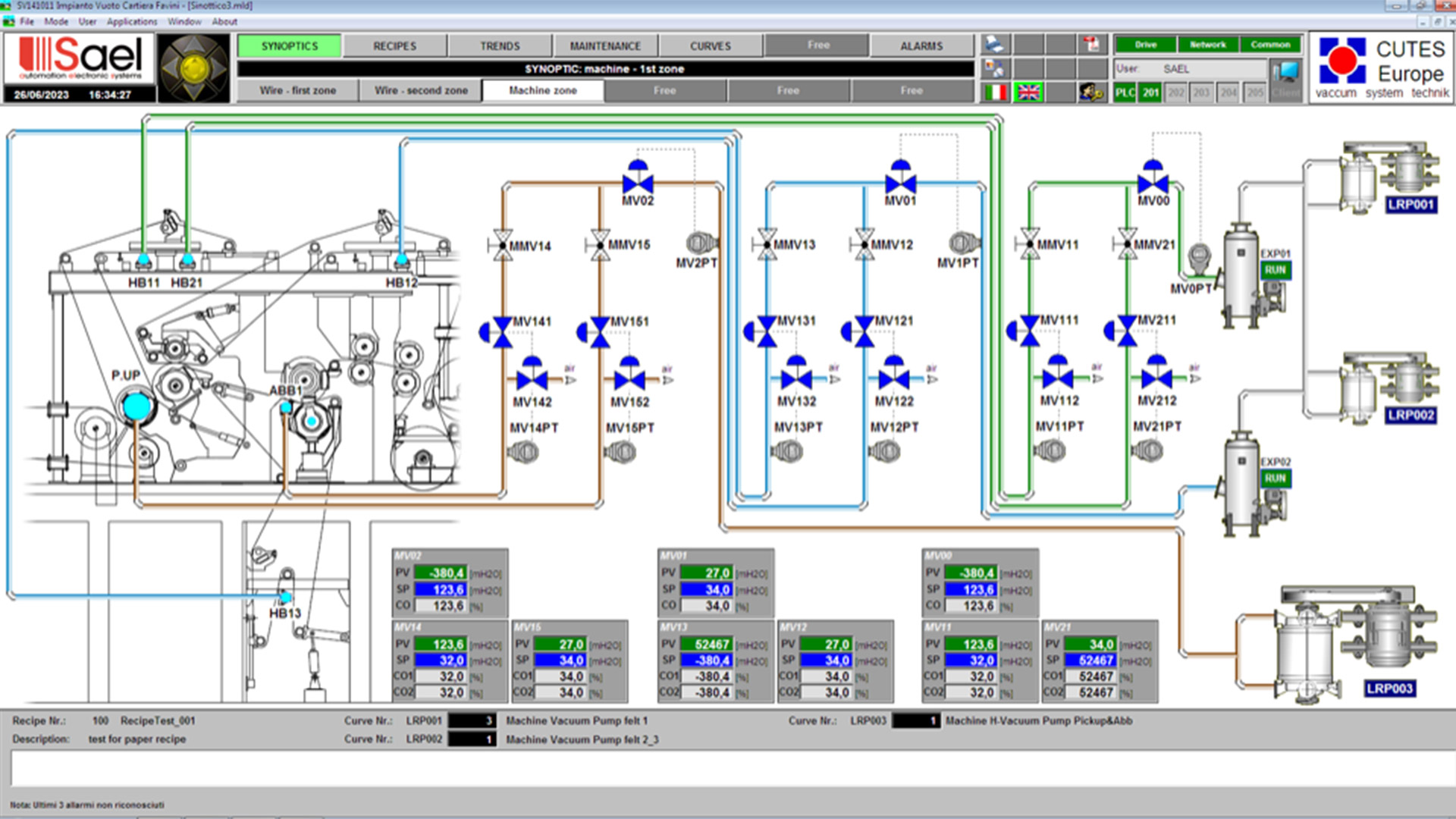

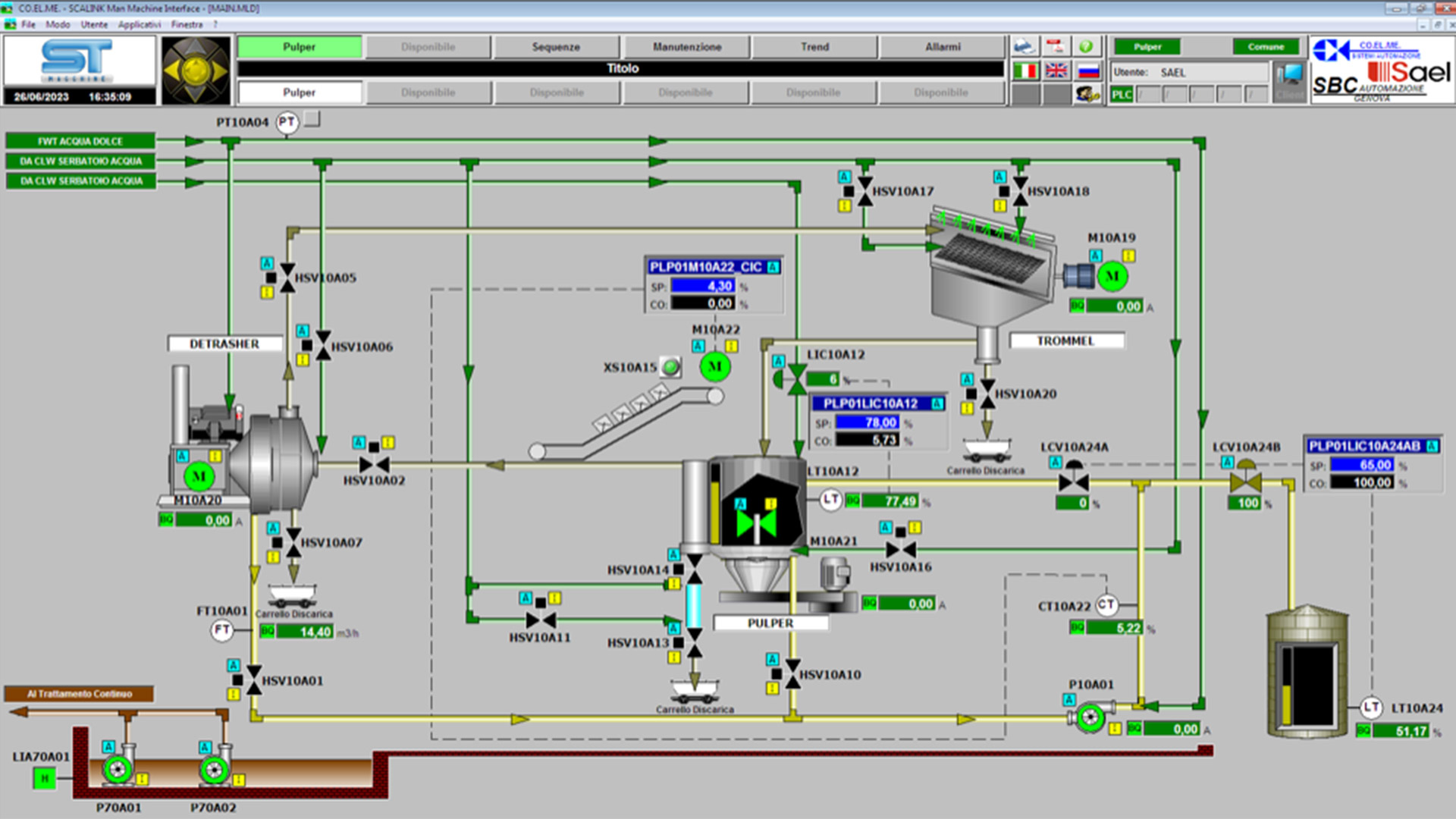

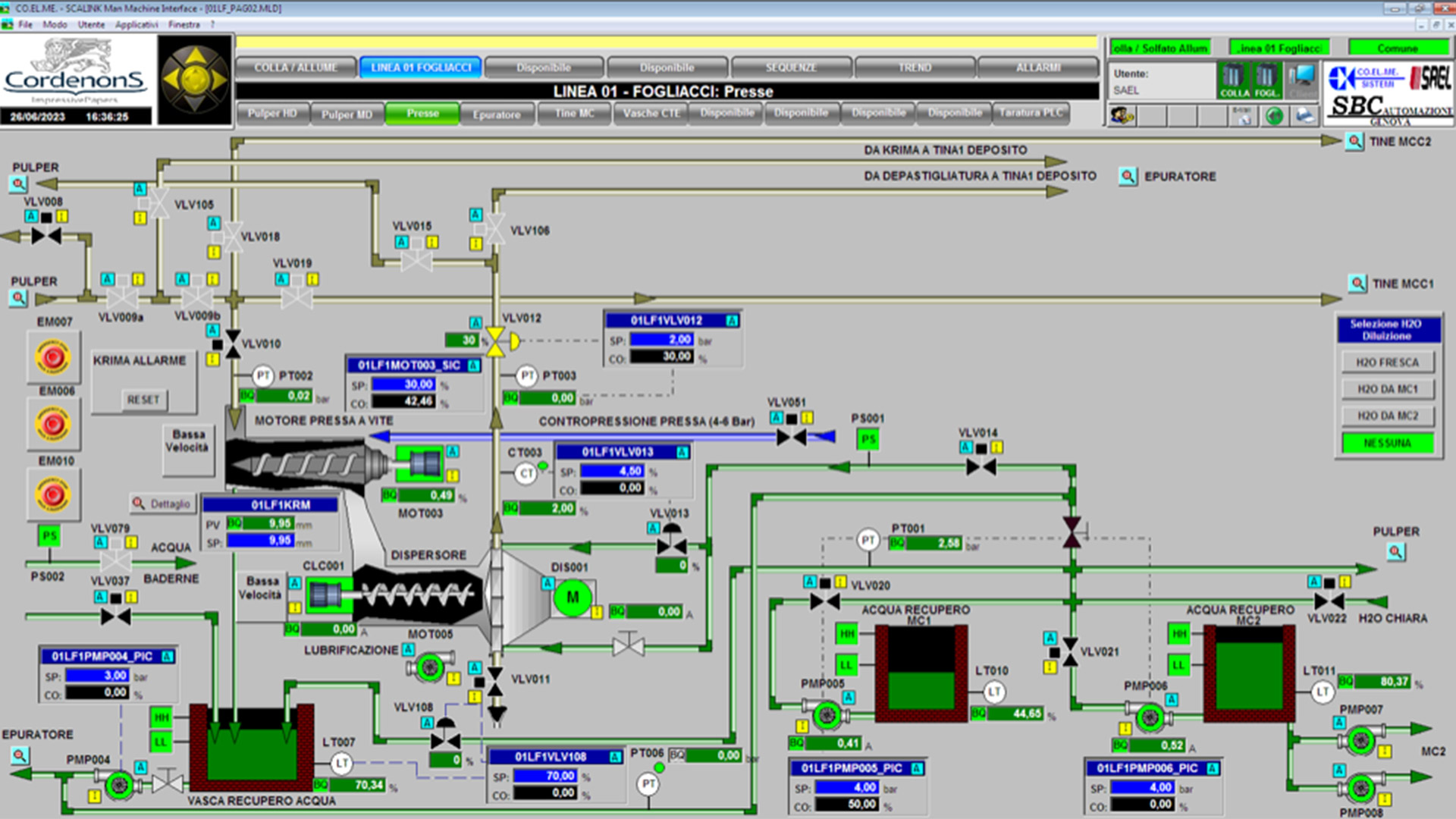

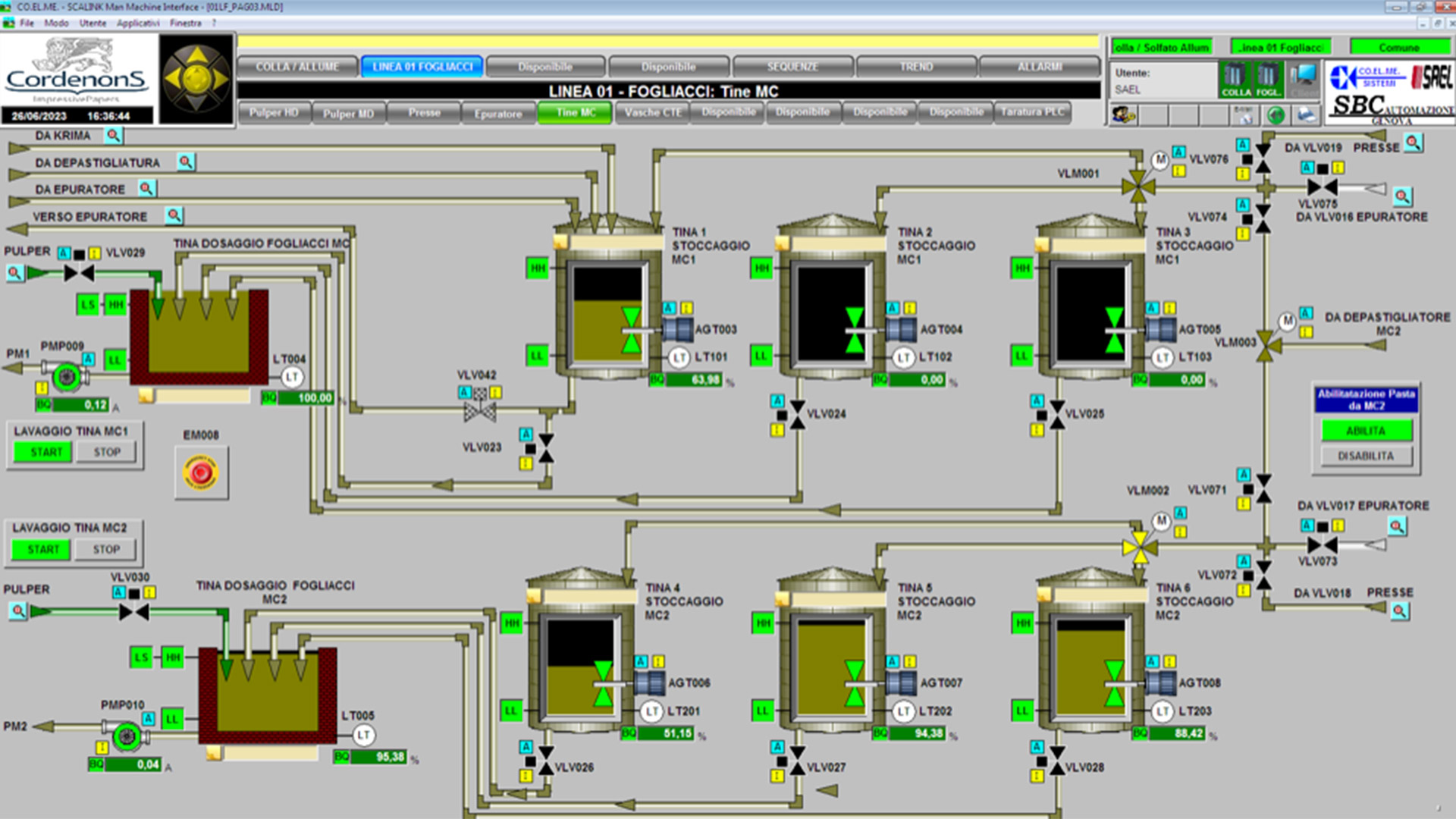

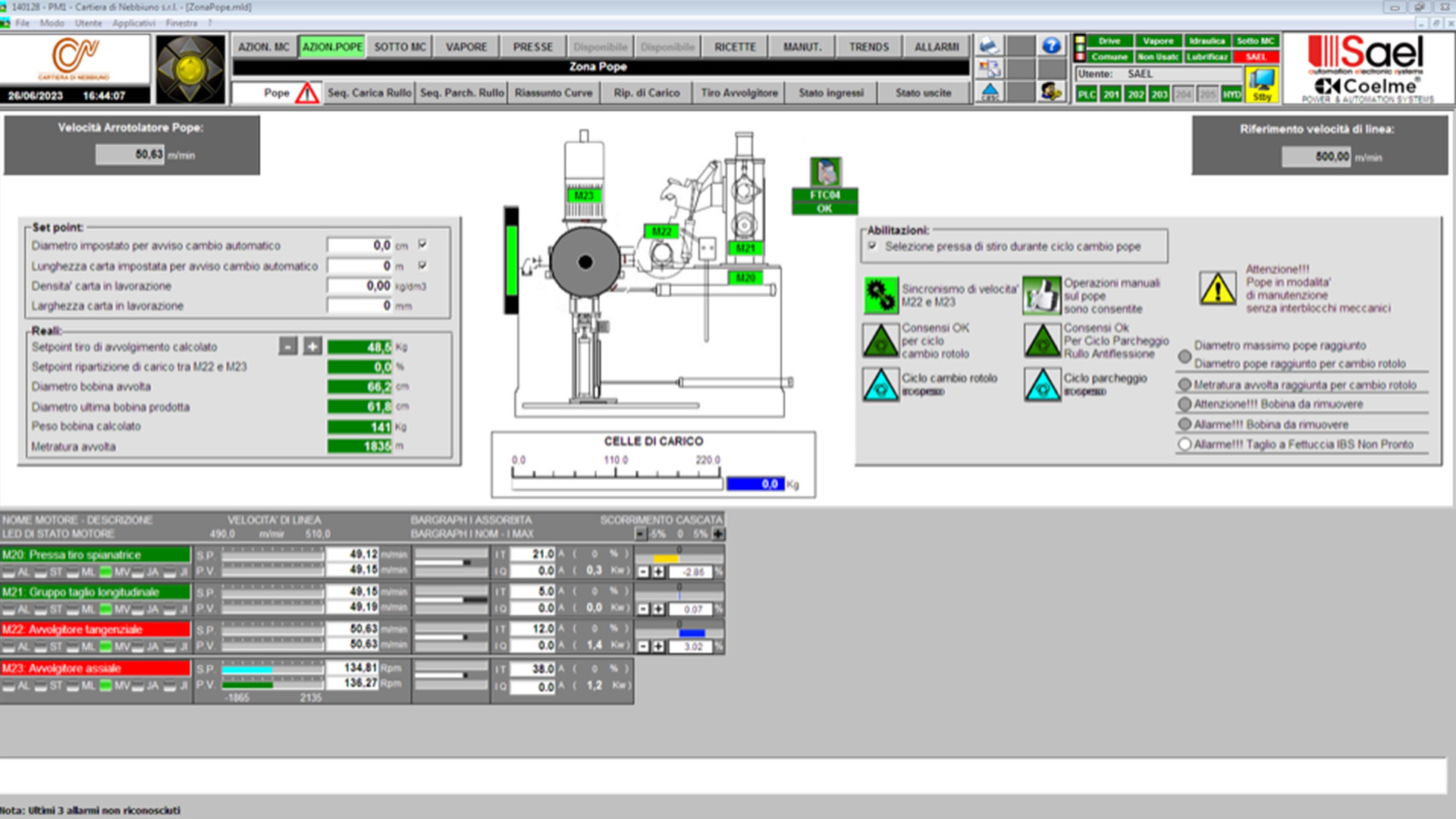

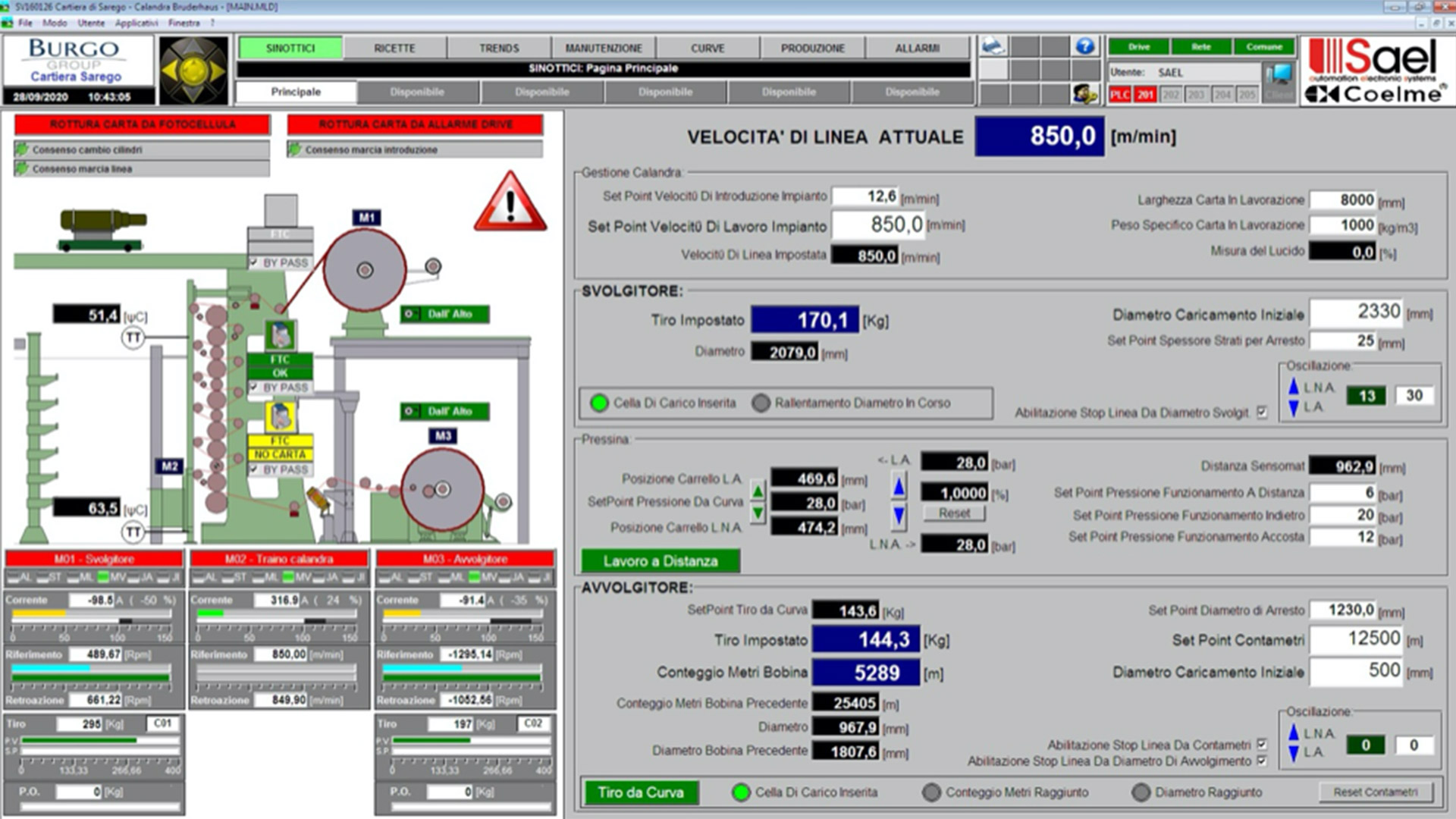

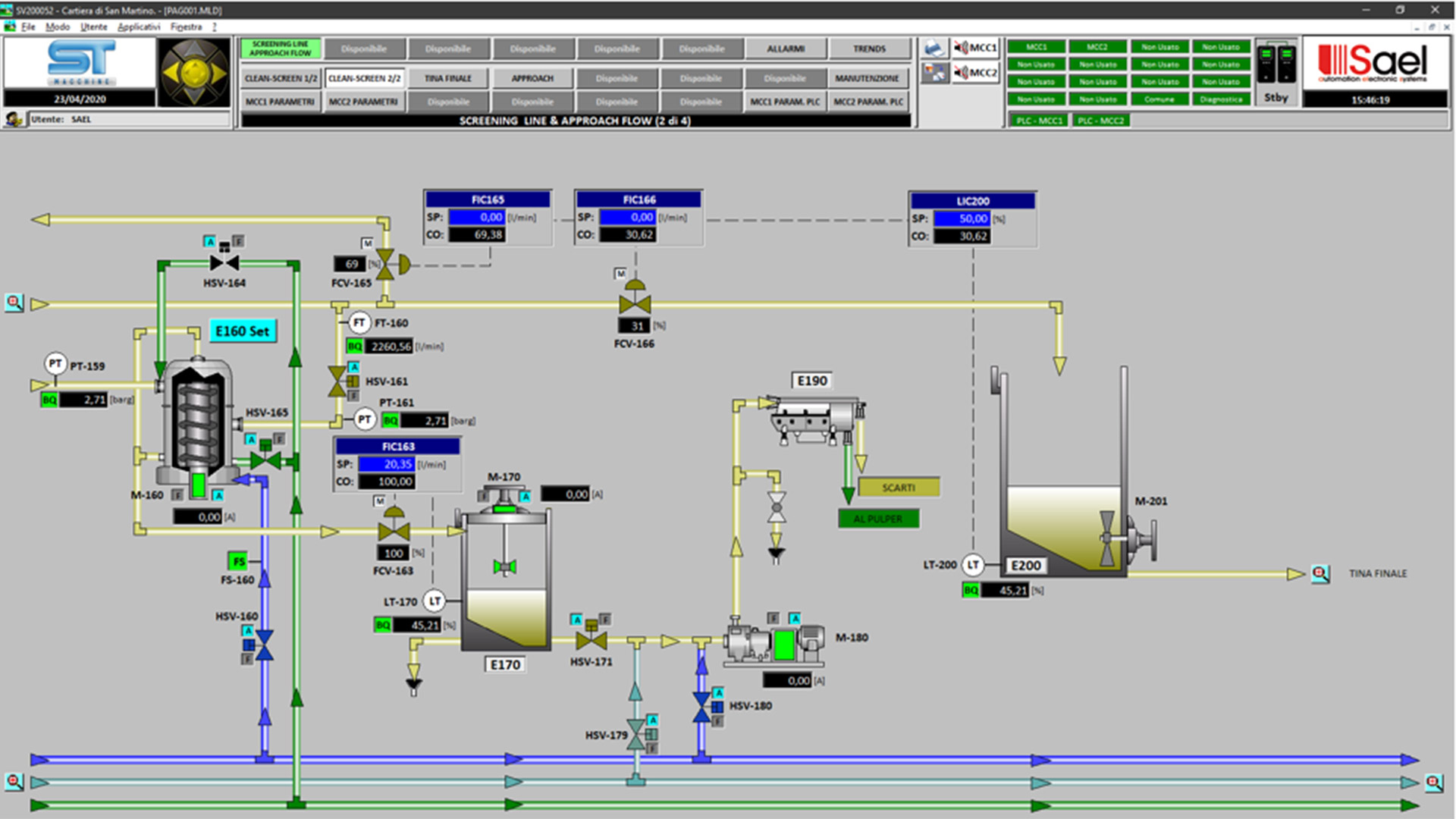

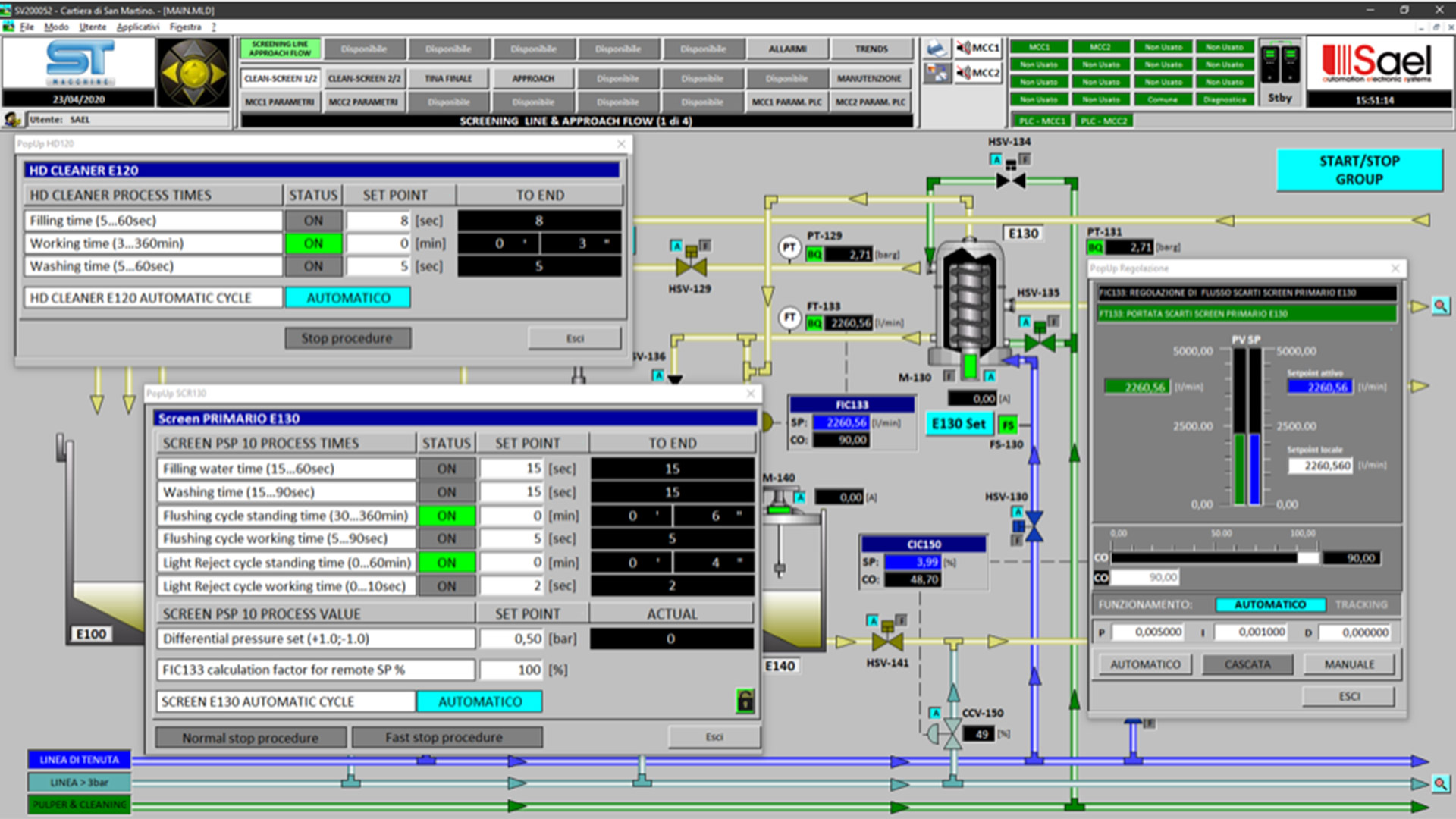

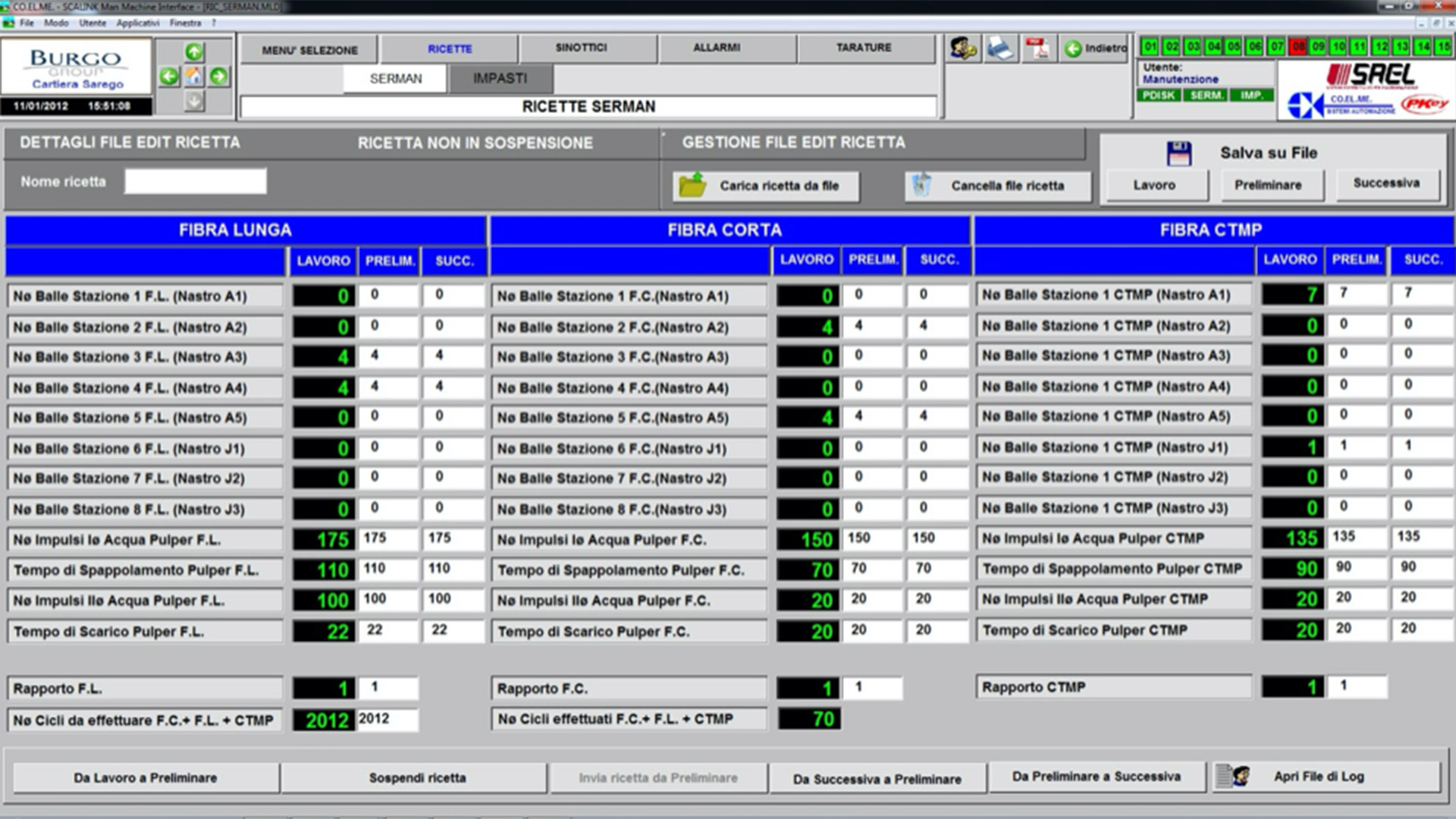

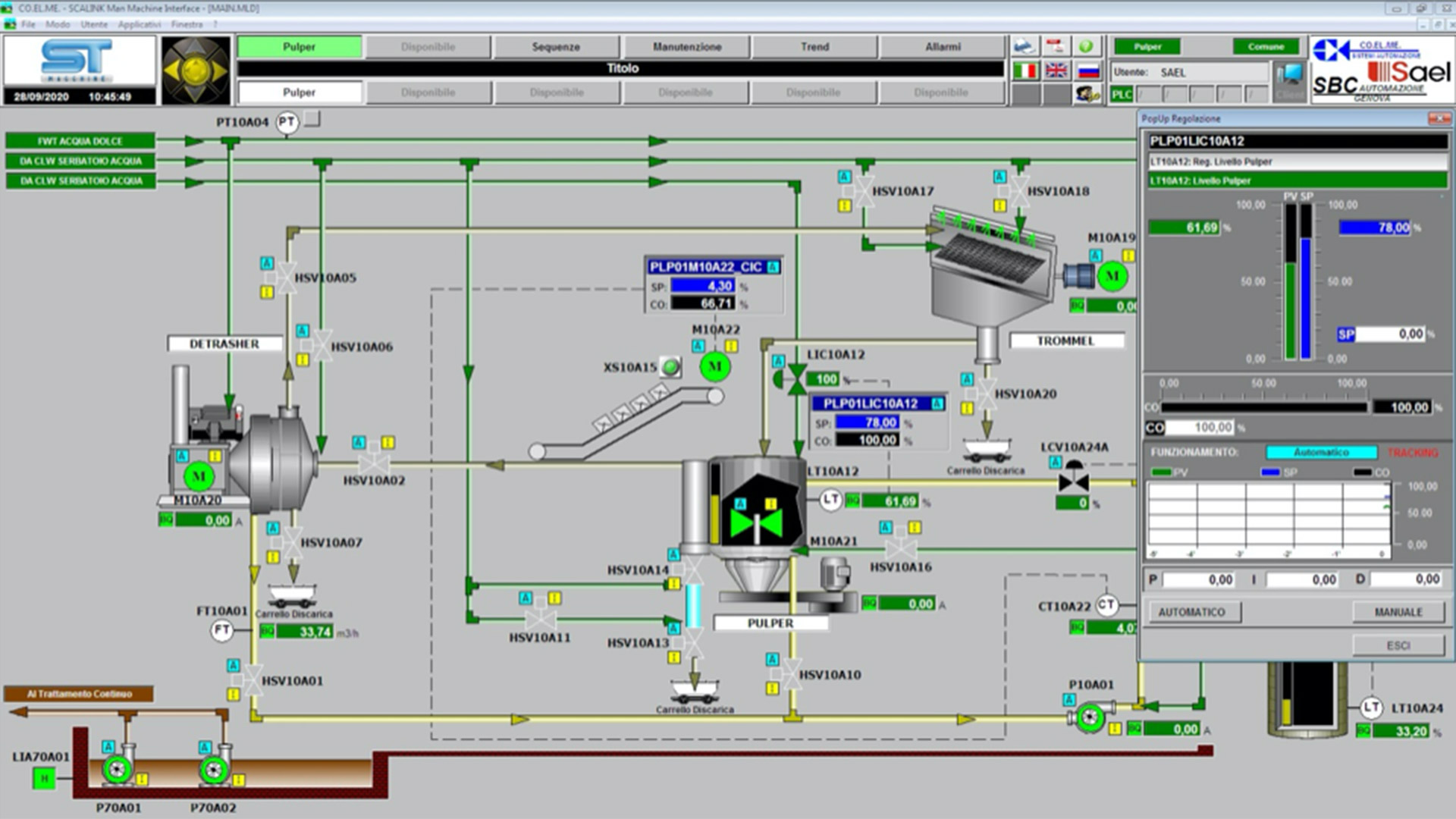

Thanks to the knowledge acquired on specific Stock Preparation SAEL makes the difference on that application. Since the first touch with the paper mill operators it is possible to dive into the system with a clear whole picture of it: each system is a powerful management tool who allows a quick and friendly approach to all the cycles. Moreover, it facilitates the direct changings to the process.

Behind this easy management there are powerful algorithms within our owns software tools.

— Architectures

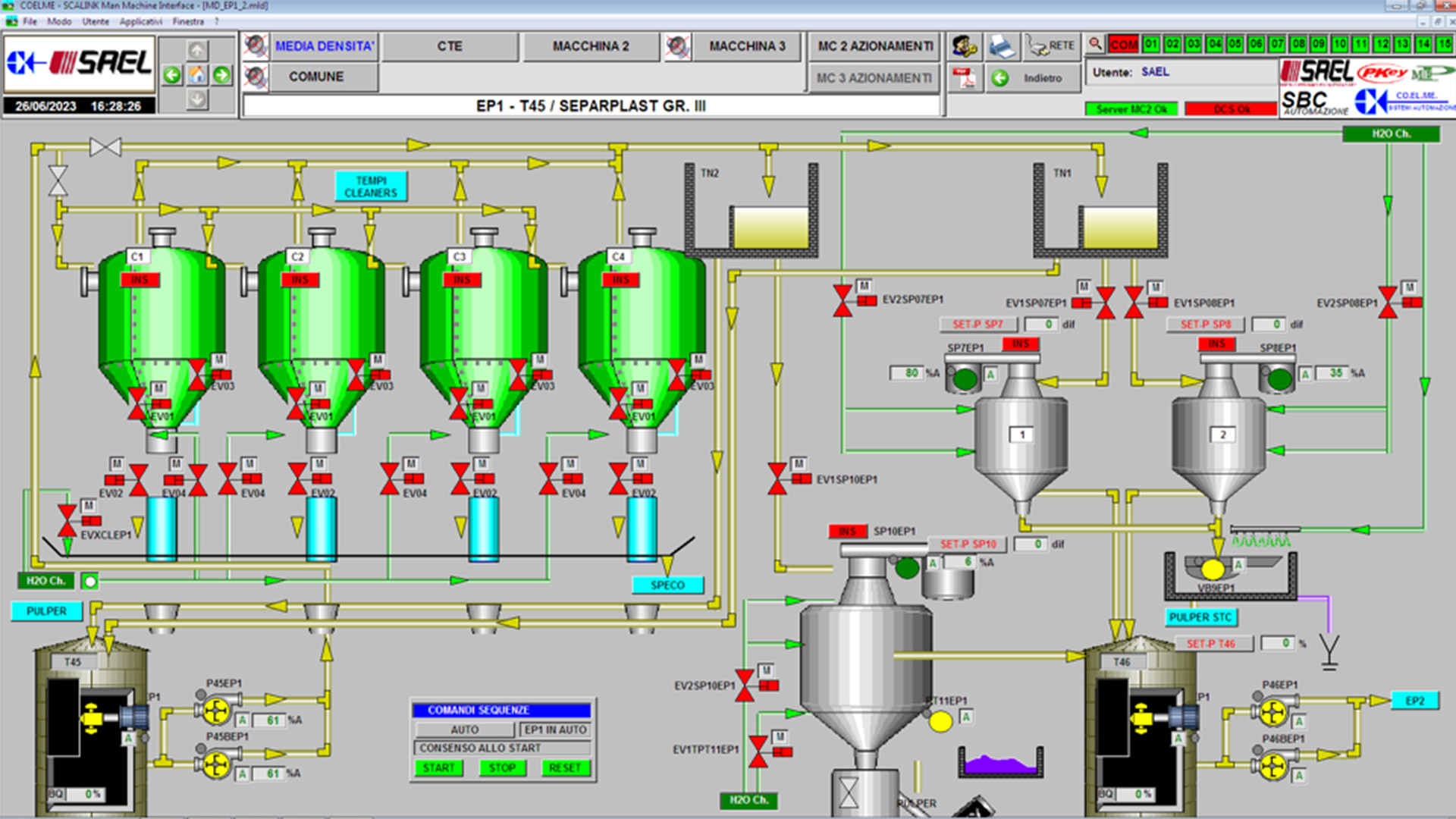

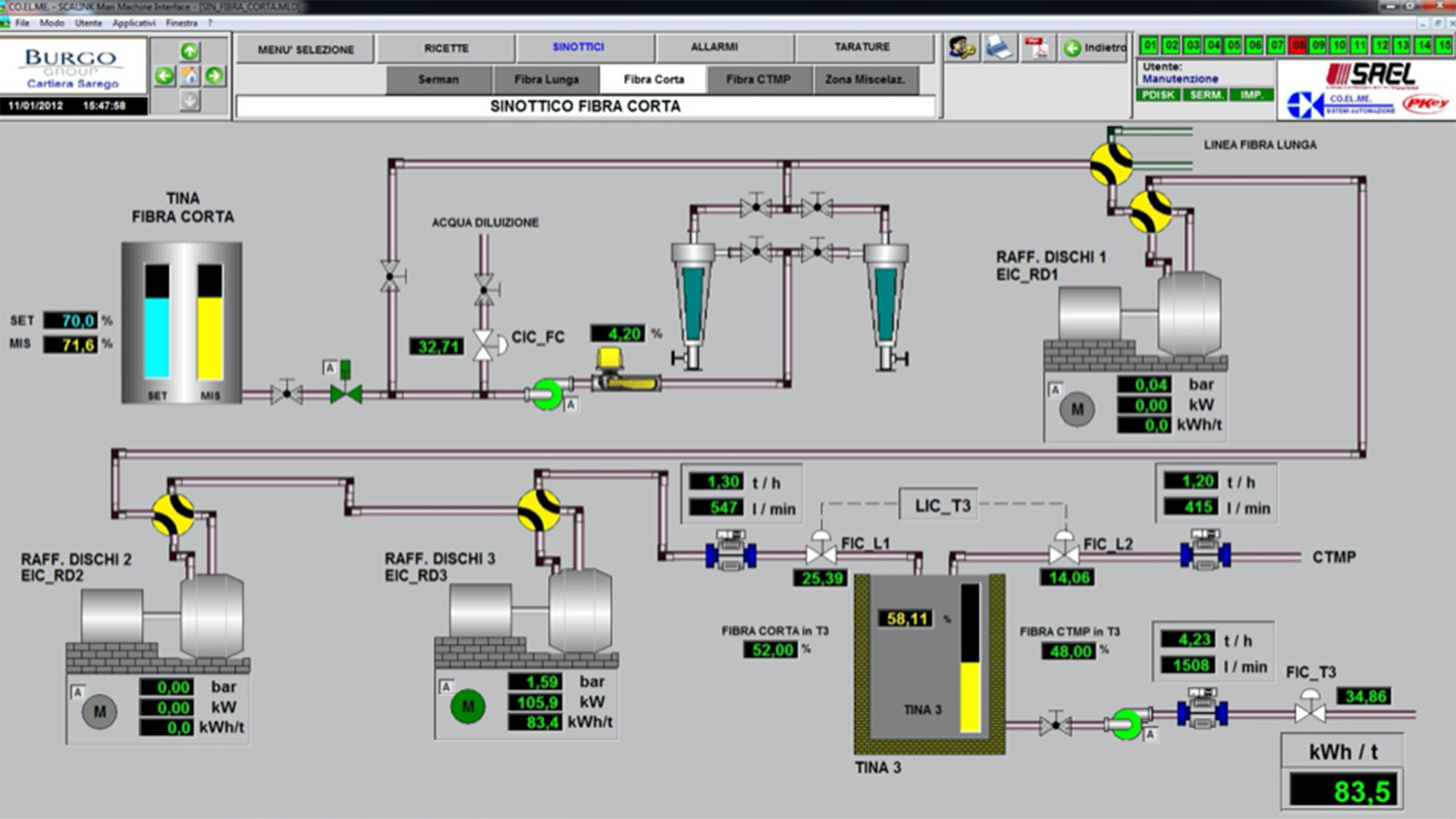

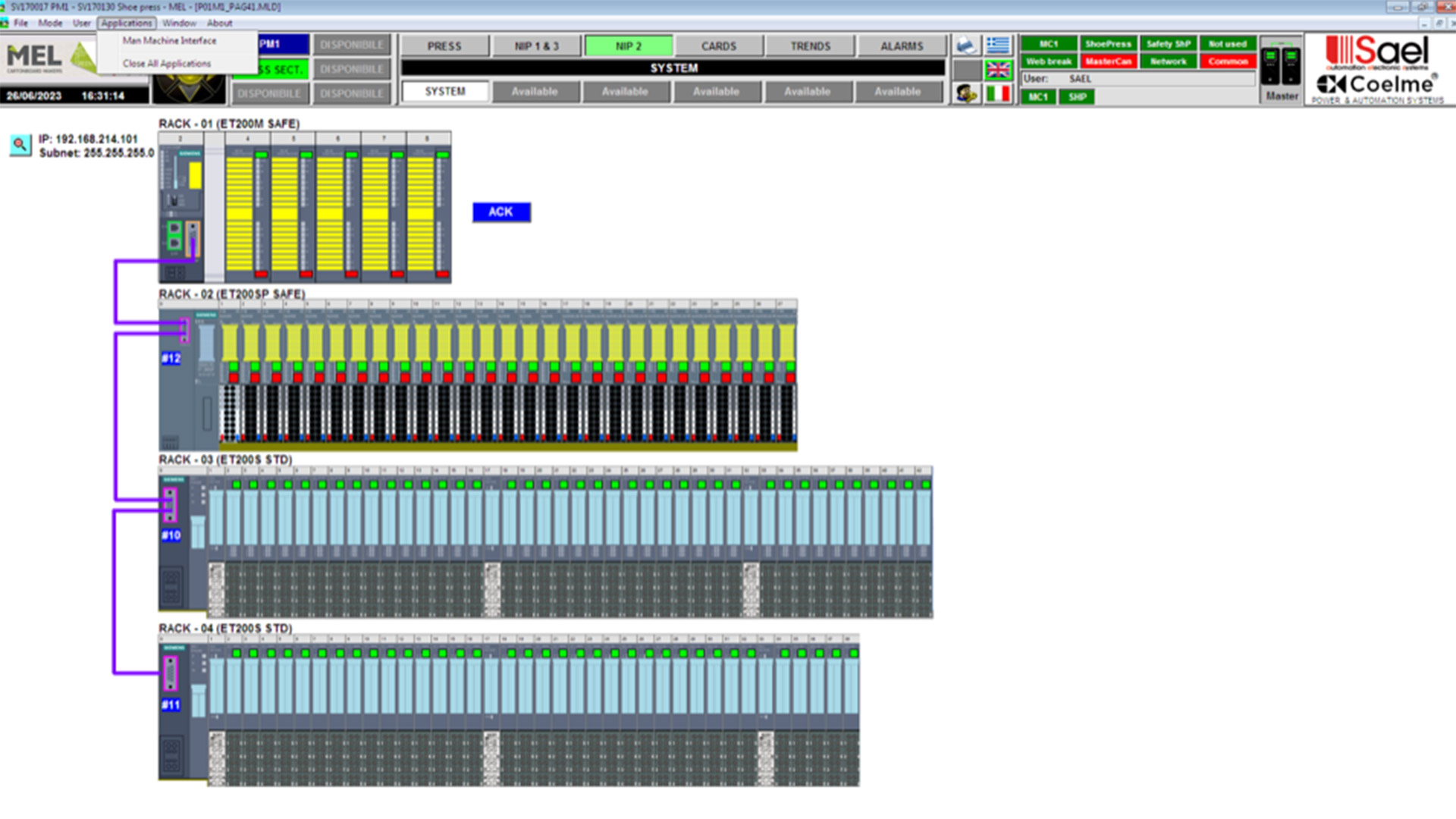

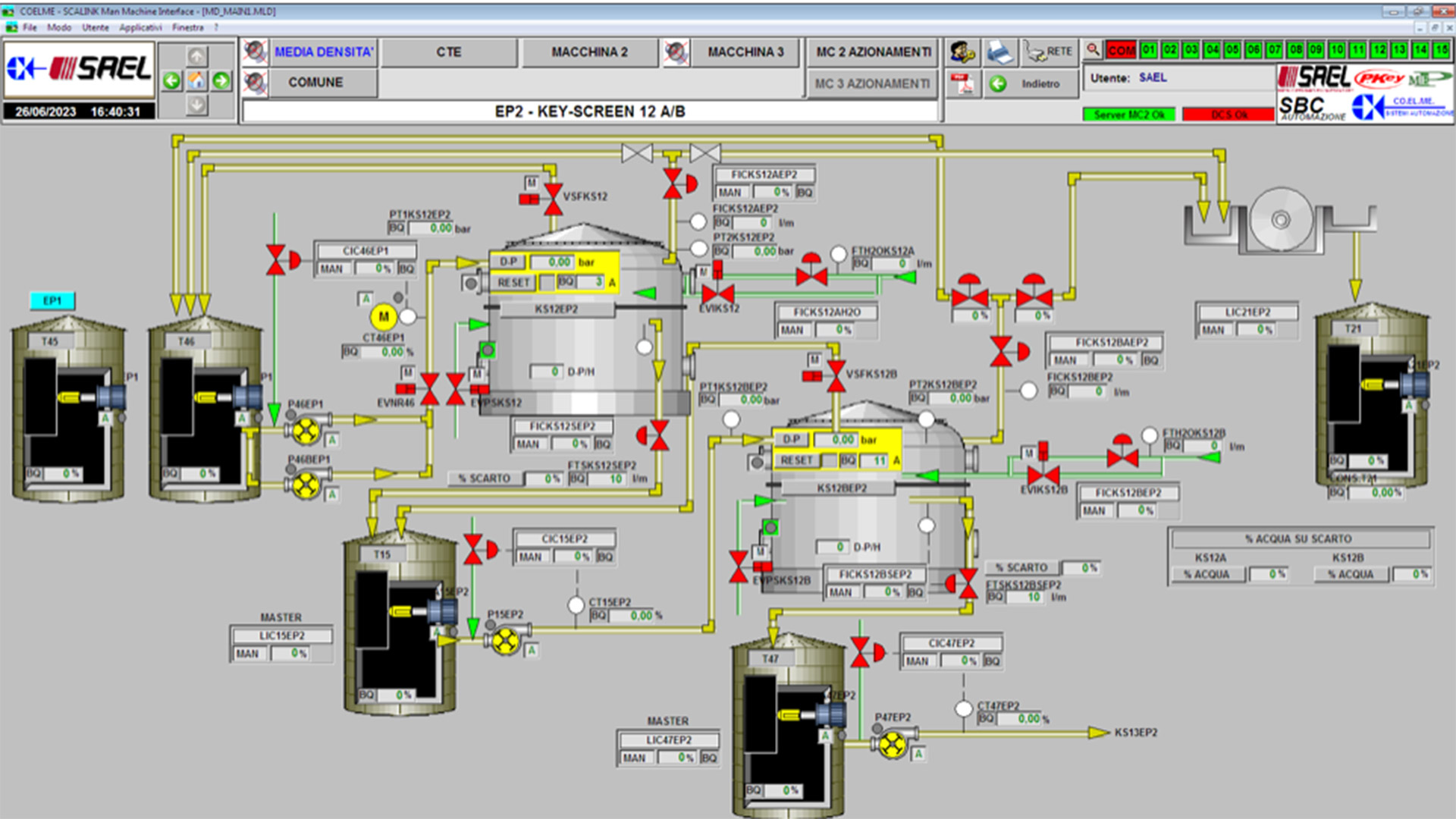

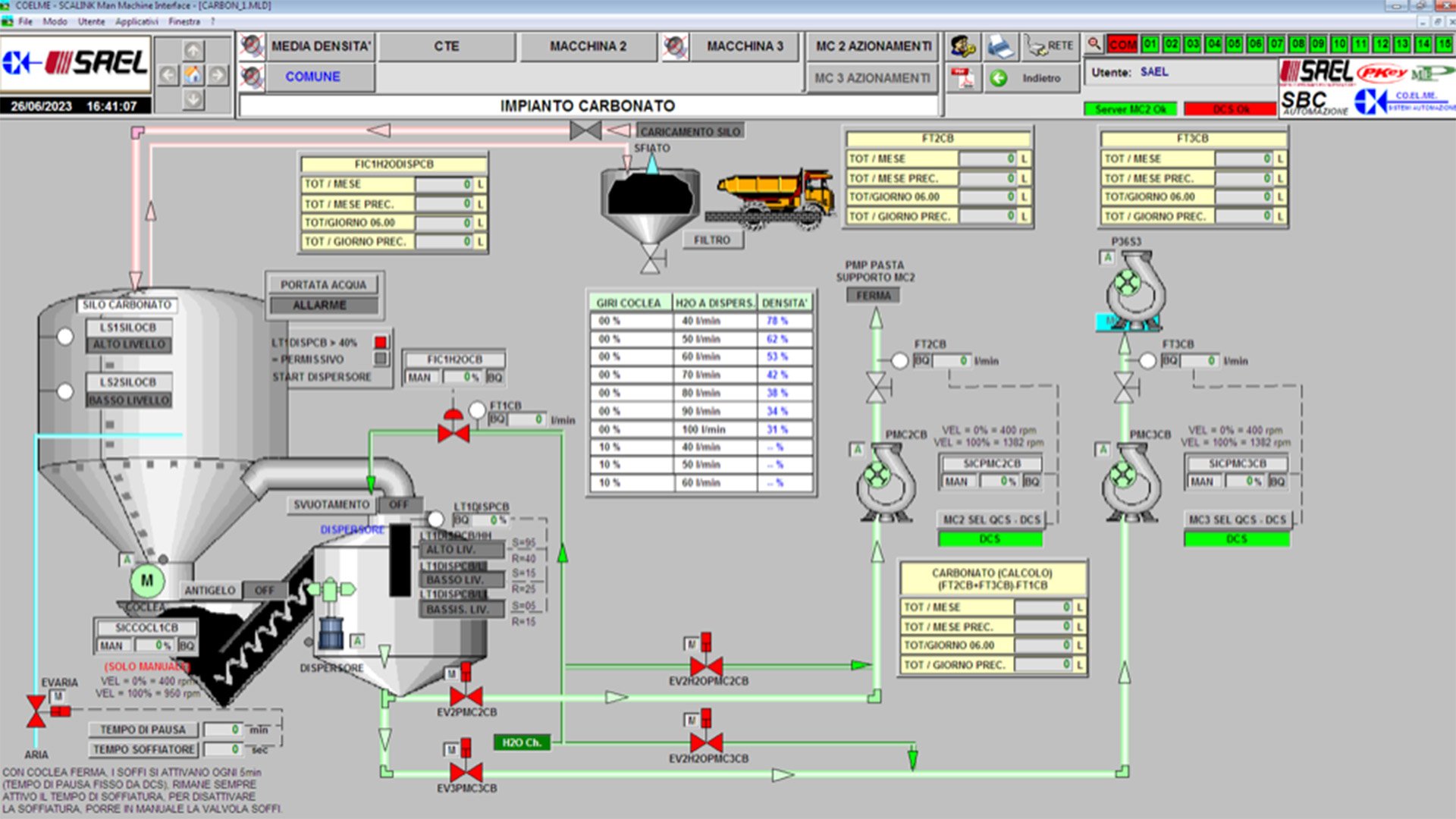

Based on customer needs there are a bunch of architectures used. From the PLC with MMI/Scada up to the most complex DCS systems that we normally supply to our customers.

By those systems it is possible to manage all the menu variables – for water, pulp, additives, market paper -as much as the active power for each refiner group; the kwh/Ton set- point; the levels of every color; the regulators flow; all the power-pressure-positioning-consistency transducers; cooking coatings. From the system it is possible to enable / unable all the functions on the monitor . Every data is stored into the DCS Scalink second by second: the system can be upgraded and enlarged in a second time without limits. As soon as there is a second PC driving station the systems gets the redundancy function. Each PC can run up to 4 monitors at the same time. The PC stations can be replaced without any software installation: a simple Scalink directory hard copy and the transferring to an USB key is required.

Are you interested in learning more?

Contact us by filling out the form