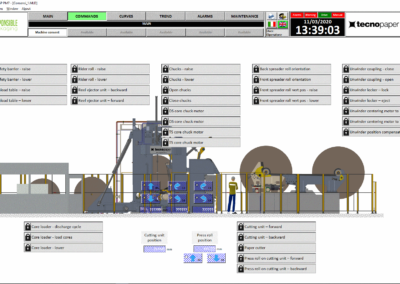

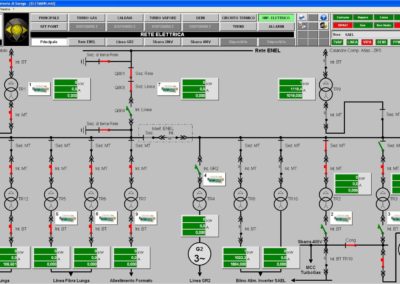

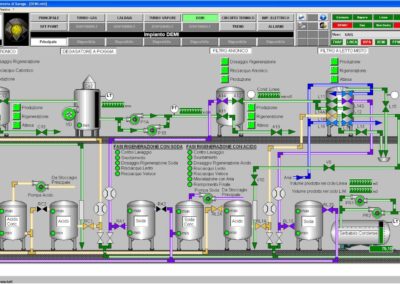

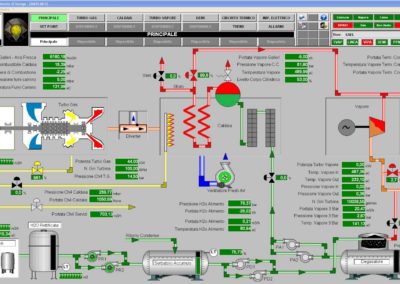

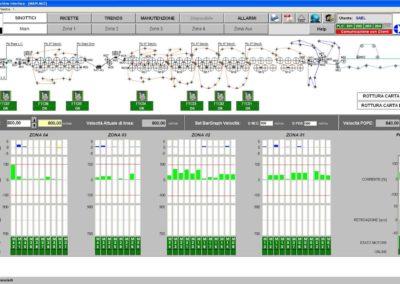

— Supervisor – Engineering station

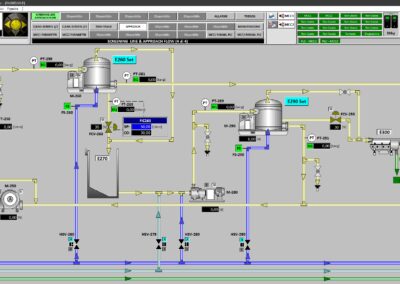

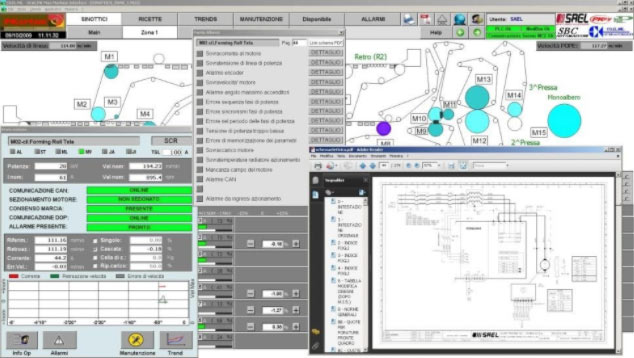

The architecture is based on WINDOWS with driving programs on SCALINK and MMI-SCADA platforms: fully available to whom has the programming key. The complete package is completed by the remote assistance IWSA – Internet World Sael Assistance – installed on every drive and 6 month free of charge after the take in place.

— Technical deepening

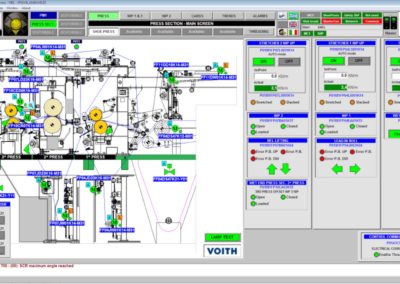

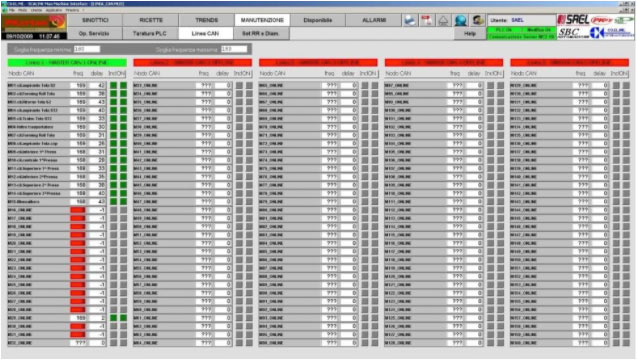

PLC programming, as well as the Drives programming, is transparent and directly made via supervisor.

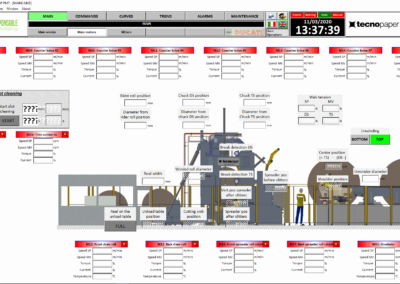

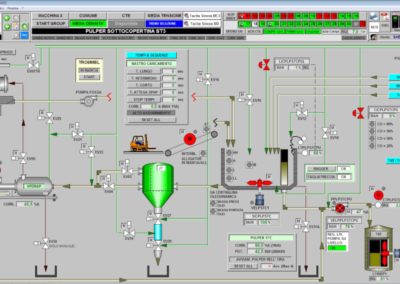

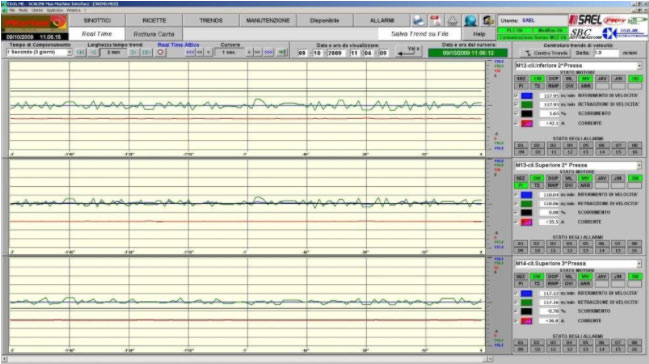

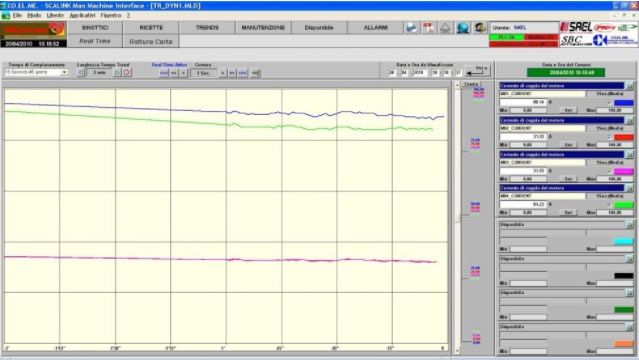

Historical Trends up to 45 days (and extendable upon demand) of all the motor variables and subdivided on three different sampling time (1sec – 5sec – 15sec). In the motor trends there are other variables like drives unlock and alarm status.

The motor trend shows all the variables (no search is required), and you can get up to three motors configuration simultaneously – selectable by a scroll menu –

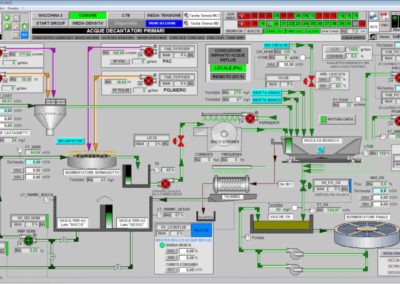

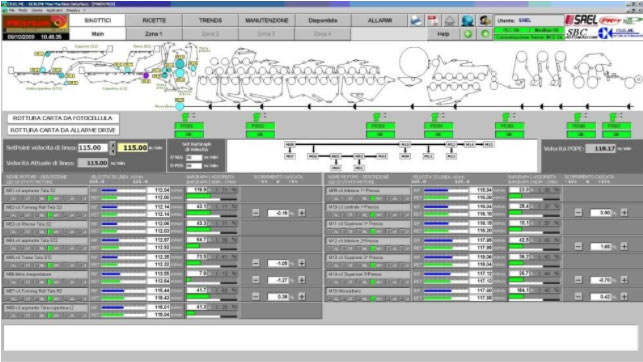

Paper break via photocell: automatic variables motor storage, three minutes before and after the event. All is triggered by the photocell and to a quick control, the file shows the motor name as well as hour and data event.

Paper break via Drive: automatic variables motor storage, three minutes before and after the event. All is triggered by the Drive and to a quick control, the file shows the motor name as well as hour and data event.

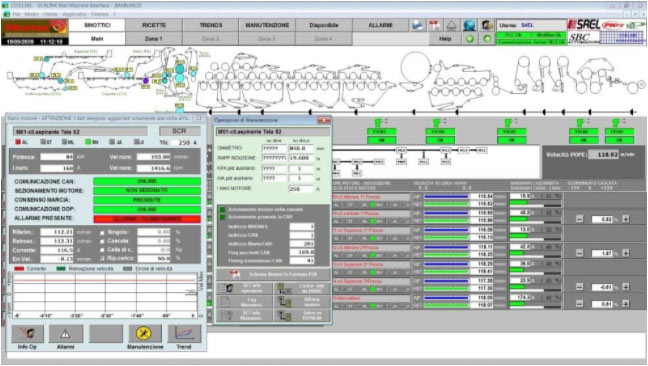

Motor management POUPUP with all the set points and variables of the selected motor. All the parameters can be settled by this page.

Motor alignment POUPUP for an accurate start up activity of the system.

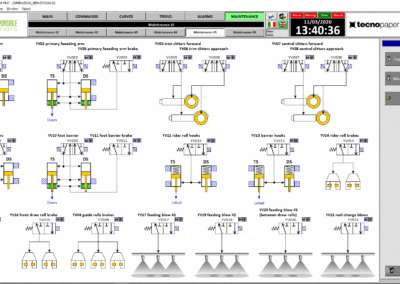

Motor maintenance POUPUP with Drive regulations settings.

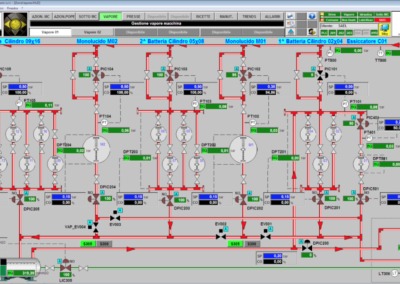

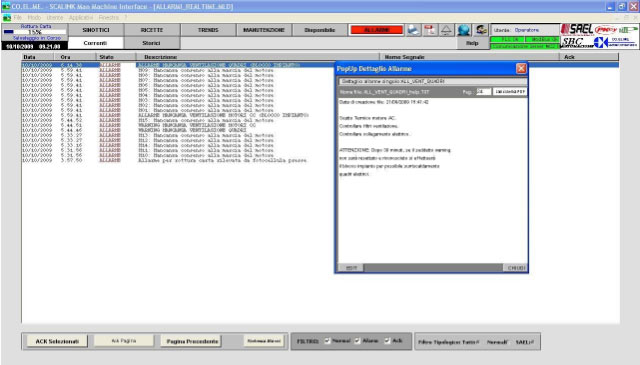

Advanced diagnostic with Help of every single alarm editable by the paper mill operators. In this way it is possible to track all the electrical activities (related to the alarms) and easier replacement of the anomalies – by not expertise personnel too -. All the on-line guides and help are a big added value for this specific activity.

Electrical diagrams automatic opening, and link to the single alarm case.

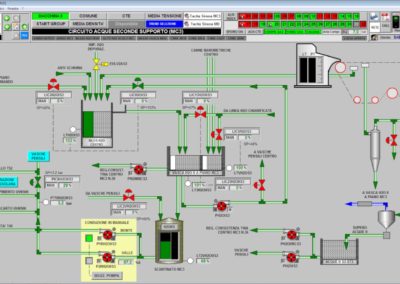

The supervisor can be integrated everywhere because is Open and perfectly fits with the Windows system as well as any existing Hardware in the market.

The OPC server and DDE server – inside function of SCALINK – allows the data exchanging with the present supervisors in the paper mill. This means a perfect integrating of our system with the paper mill existing tool.

Moreover, it is possible to enclose photos and video to the comments.

Every alarm is linked to a text and page number enclosed in the supervisor.

Are you interested in learning more?

Contact us by filling out the form